1.Application of HH-1+6+12 Planetary Stranding Machine

This machine is designed for cabling of insulated conductors (control cables/signal cables/small power cables) stranding of copper wires/soft copper wires (bunched strands)

The planetary standing machine's reel frames utilize a novel parallel gear back-twist mechanism. The planetary gears behind the first capstan are each connected to a back-twist shaft equally spaced outside the main shaft, driving the shaft's rotation. Each reel frame receives back-twist torque from the back-twist shaft via a set of gears. This ensures that each reel frame within the stranding cage bears only its own torque, and each reel frame experiences equal torque. This eliminates the torque and gear backlash stacking that occurs in series structures.

| Parameter | Specification | Details |

| 2.1 Wire Diameter | Insulated Wire | 0.65-4.0mm |

| Soft Copper Wire | 0.5-3.0mm | |

| 2.2 Cage Rotation Speed | 6-bobbin | 9-80 rpm (Stepless) |

| 12-bobbin | 8-70 rpm (Stepless) | |

| 2.3 Take-up Line Speed | 2.0-40 m/min (Stepless) | |

| 2.5 Stranding Pitch | 6-bobbin | 25-2000mm (Stepless) |

| 12-bobbin | 29-2000mm (Stepless) | |

| 2.6 Wrapping Head Speed | 50-800 rpm (Stepless) | |

| 2.7 Wrapping Pitch | 5-300mm (Stepless) | |

| 2.8 Inner Pay-off Bobbin | PN400 (Customer provides drawings) | |

| 2.9 Outer Pay-off Bobbin | PN400 | |

| 2.10 Take-up Bobbin | PN800-PN1600 | |

| 2.11 Motor Power | 6-bobbin | 22kW (BEIDE VFD) |

| 12-bobbin | 30kW (BEIDE VFD) | |

| Take-up | 11kW (BEIDE VFD) | |

| Wrapping | 2.2kW (BEIDE VFD) | |

| 2.12 Machine Center Height | 1000mm |

| No. | Items | Quantity |

| 1 | Φ400 Active Pay-off Stand | 1 set |

| 2 | Cross Wire Guide Stand | 1 set |

| 3 | JY400ZF/6+12 Main Stranding Cage | 1 set each |

| 4 | Stranding Die Holder | 2 sets |

| 5 | Φ400 Concentric Paper Wrapping Head | 1 set |

| 6 | Length Counter | 1 set |

| 7 | Φ1250 Traction Unit | 1 set |

| 8 | Φ400 Swing-arm Tensioner | 1 set |

| 9 | Φ1600 Gantry Take-up Stand | 1 set |

| 10 | Electrical Control System | 1 set |

| 11 | Foundation Bolts | Full set |

1. Φ400 Active Pay-off Stand

| No. | Items | Feature | Detail |

| 1 | Bobbin Specifications Standard | PN400 | |

| 2 | Drive Mechanism |

Pneumatic clamping

Motorized lifting End-shaft structure |

|

| 3 | Tension Control System |

Swing-arm wire storage device

Mechanical counterweight tension adjustment (calibrated scale) |

|

| 4 | Active Pay-off Features |

VFD motor controller

PID control with angular displacement sensor ≥98% operational stability |

2. JY400ZF/6+12 Main Stranding Cage (Active Pay-off)

| No. | Items | Feature | Detail |

| 1 | Drive System |

Individual motor drive (motor-reducer direct coupling)

Hardened gears (carburized & ground) Forced lubrication with oil pump |

|

| 2 | Cage Structure |

Hollow shaft

Stranding discs Bobbin holders Strand guides (including hemp wrapping device) Dual spherical roller bearings support |

|

| 3 | Planetary Untwisting Mechanism |

6 planetary gears

Independent untwisting per bobbin Eliminates cumulative gear backlash |

|

| 4 | Stranding Cage Bobbin Pay-off System |

Drive Type: Active pay-off

with

VFD gear motor

Buffer Wheel: Aluminum alloy construction Tension Control: Magnetic hysteresis clutch (constant tension) Safety Features: Wire breakage & depletion protection |

|

| 5 | Tension Disc Assembly |

Torque Transmission: End-face friction discs (eliminates backlash during motor reversal)

Bobbin Mounting: Manual loading system Locking Mechanism: Dual security (trapezoidal thread + spring-loaded pin) |

|

| 6 | Braking System type | Planar pneumatic brake |

3. Concentric Wrapping Head

| No. | Items | Feature | Details |

| 1 | Core Passage | Ø51mm | |

| 2 | Tape Spool | Ø400×Ø76×(10-80)mm | 10 spool capacity |

| 3 | Speed | 50-800 rpm (stepless) | |

| 4 | Pitch | 3-300mm (adjustable) | |

| 5 | Motor | 2.2kW VFD | |

| 6 | Tension Control | Magnetic hysteresis brake + PLC | Touchscreen setting |

| 7 | Safety | Emergency stop button |

4. Meter Counter

| No. | Items | Feature | Details |

| 1 | Type | Dual mechanical/electronic | |

| 2 | Wheel Circumference | 500mm | |

| 3 | Max Length | 9999m | |

| 4 | Accuracy | ≤0.4% | |

| 5 | Drive | Dual active wheels | Spring-loaded pressure |

| 6 | Sensor | Non-contact magnetic probe |

5.Ø1250 Dual-wheel Traction

| No. | Items | Feature | Details |

| 1 | Wheels | Ø1250mm (dual active drive) | Natural strand separation |

| 2 | Speed | 2-40 m/min (stepless) | |

| 3 | Motor | 18.5kW | |

| 4 | Grooves | 6 U-shaped | |

| 5 | Design | Staggered angle + support rod | Prevents cable pinching |

6.Ø400 Swing-arm Tensioner

| No. | Items | Feature | Details |

| 1 | Wheels | Ø400mm (groove base) | |

| 2 | Groove | Ø40mm radius | |

| 3 | Tension Control | Pneumatic (pressure valve) | Lever principle |

| 4 | Feedback | Angular displacement sensor | Speed signal to take-up motor |

7.Ø1600 Gantry Take-up

| No. | Items | Feature | Details |

| 1 | Bobbin Size | PN800-PN1600 | |

| 2 | Capacity | 5T max | |

| 3 | Speed | 45 m/min max | |

| 4 | Motors |

Take-up: 4kW

Traverse: 0.75kW Lift: 0.75kW Clamp: 0.75kW |

|

| 5 | Features |

Automatic centering

Motorized bobbin handling PID control via tension feedback |

|

| 6 | Safety | Clamping/limit switches |

8.Electrical Control

| No. | Items | Feature | Details |

| 1 | Power | 380V±10%, 50Hz (3P+PE+N) | |

| 2 | Components |

Siemens VFDs & PLC

Schneider low-voltage Siemens HMI WEG |

|

| 3 | Safety |

Delayed start after alarm

Emergency stops on all stations |

5.Others

| Items | Description | Details | Responsibilities |

| 1 | Total Installed Power | 85 kVA | - |

| 2 | Operation Orientation |

Right-hand operation layout:

• Left side: Pay-off • Right side: Take-up |

(Facing machine control panel) |

| 3 | Color Scheme | To be provided by customer (color samples required) | Customer to specify |

| 4 | Documentation Provided |

• Operation manual

• Equipment layout drawings • Foundation drawings • Piping diagrams • Drive system schematics |

Supplier provides |

| 5 | Customer Responsibilities |

• Compressed air supply (0.6-0.8MPa)

• Bobbin technical drawings (for PN400/PN630/PN1600) |

Customer provides |

| 6 | Installation Scope | ||

| 7 | Supplier Responsibilities | • Internal wiring (within machines/control cabinets) | Supplier completes |

| 8 | Customer Responsibilities |

• Inter-machine cabling

• Gearbox oil • Leveling shims • Installation tools |

Customer provides |

Modern factory, scale production, precision operation

| Professional Engineers and Experienced Sales Team | |||||

| Name | Education | Position | Mainly responsible for project | Specializing in project | Working history ( year ) |

| Zanyang Xie | college | General Engineer | The total project design and planning | power cable machine | 15 |

| Xiaohua Hu | college | Vis general engineer | The total project design and planning | net cable,data cable machine | 10 |

| Changhong Cheng | college | Engineer | Drawings and after-sales service | Optical fiber cable machine | 25 |

| Xiuwu Chen | college | General Engineer | The total project design and planning | copper drawing machine | 15 |

| Lixin Yuan | college | Engineer | The project design and planning | coppwer wire making technical | 16 |

| Zhenghai Qiu | college | cable engineer | After service | cable making and cable factory management servie | 15 |

| Jinxin Liu | college | Marketing engineer | After service | electrical engineer | 7 |

| Xingguo Tang | High school | Electrical engineer | After service | electrical engineer | 10 |

| Changqiang Li | High school | Maintain engineer | After service | machina maintain and install service | 10 |

| Haipin Li | University | Engineering director | Marketing and sales | project consulting | 8 |

| Sen Yang | University | Engineering translator | Marketing and sales | project consulting | 10 |

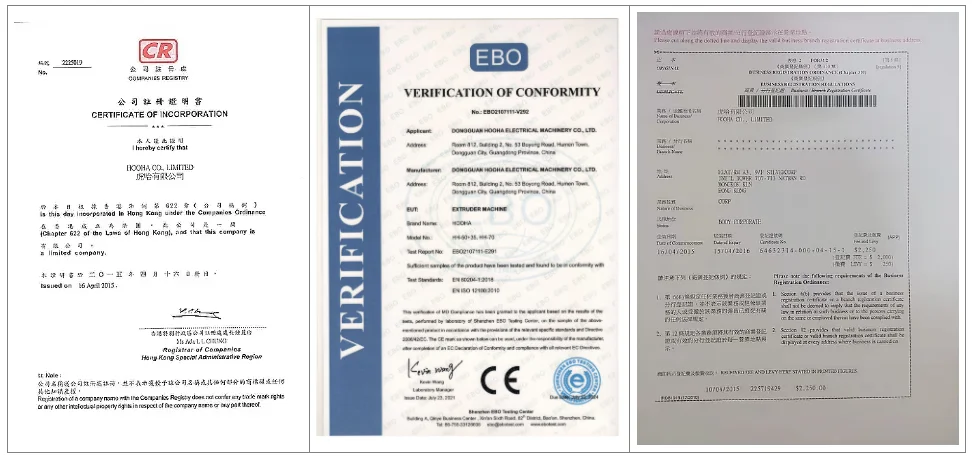

7.Certificates of HOOHA

|

|

|

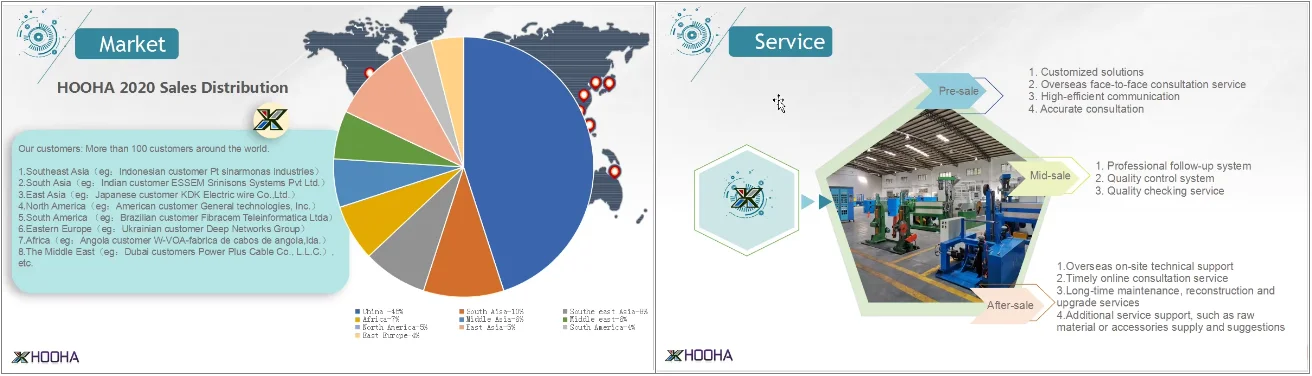

Hooha company Limited is based in Hongkong, china.Factory is located in dongguan,China.Established in 2003, with 19 years of experience in wire and cable field trade.It only takes 1 hour from our company to guangzhou/shenzhen airport.

2.How can we guarantee quality?

1.Online inspect facotry,production,shipment,and aftersales services.

2.pre-production sample before mass production.

3.High standards and strict requirements, key accessories of cable equipment only use imported parts.

4.Mechnical parts gurantee 12months, elcctrical parts 12 months.

5.online communication,remote assistance,solve customer problem 24 hours,when the problem can not solved online,we will dispatch engineer to go aboard to the problem on-site for the customer.

3.What can you buy from us?

1.material for wire and cable

2.turkey project for wire and cable

3.extrusion line/bunching/twisting machine for wire and cable

4.accessorries for cable equipments

4.How long is your delivery time?

1.Generally, 3-7 days for goods in stock

2.30 days for goods after realsing order.

3.project will take 60-90 days

5. Will the price be cheaper if the order is placed in bulk?

Yes,Of course,it will make10%-12%discount

6.What services can we provide?

1.Plant solution and machine design.

2.technical support at machines and cable

3.Installtion and commmsioning,after sales service.

4.Packaging customization

5.Customized,saving 10%-20% year-on-year cost

7.HOOHA cable equipment technical advantages

1.In order to ensure the high quality of products,we start from ensuring the accuracy of accessories, and the main accessories of products(Casing, end cover, shaft and wheel) they are all manufactured by CNC machining center,The main purchased parts are NSK Bearings from Japan,American gates belt,taiwan TTO Fluoro rubber oil seal,The working efficiency of the equipment is improved, the noise is reduced, and the service life of the equipment is extended to more than 10 years.

2.High precision dynamic balancing of all equipment rotors,The dynamic balance level is G1, reducing the unbalance to less than 1G, and the long-term operation is safe and reliable.

3.The bearing adopts double row cylindrical roller bearing and double row self-aligning roller bearing,compared with the deep groove ball bearing, the bearing has high fatigue strength, long service life, stable operation and small vibration.

Why chose HOOHA?

Before sales

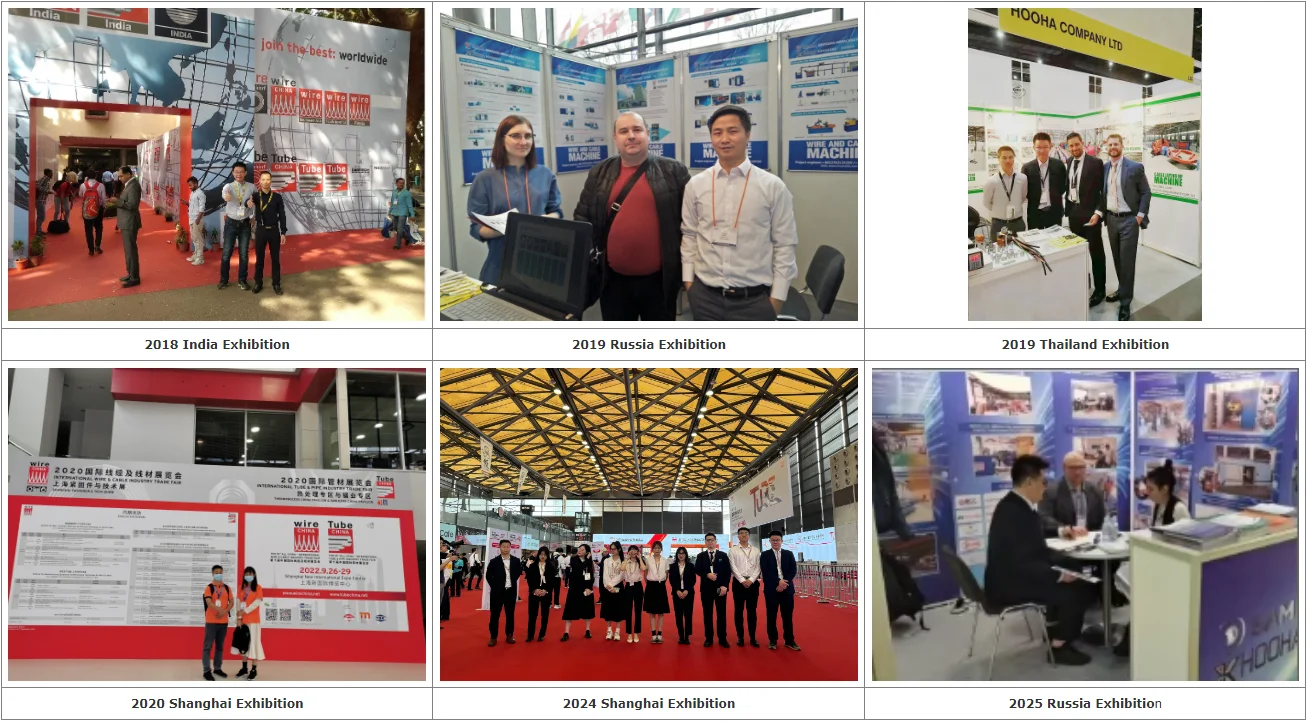

1) 88 successful turnkey factory project .

2)Help over 28 clients from around the globe build their program from the ground.

3)Most humanized cable making solution provided by professional sales team with 10 years experience .

4)Complete access for all aspect of supply chain in professional cable industry with 18 years experience , including manufacturing material , technology , testing equipment , etc .

5)For 15 years , HOOHA stand alongside the client , considering and solving from the perspective of client’s marketing angle with all-around , precise and applicable solution .

6)HOOHA help saving the communication time cost for dealing with over dozens of supplier in the supply chain , mean while clients can generate much more value with same amount of time .

Middle sales

7)10 years experience engineer team for overseas cable and wire industry manufacturing and machinery installation and maintenance .

8)10 years experience engineer planing team for whole factory project including machinery , space layout , operational plan , water air electricity consume , raw material and such .

9)10 years experience professional team working on daily management and operation craft for cable and wire factory .

Vision

1)HOOHA is willing to grow with clients and achieve a mutual victory through business .

2)HOOHA spare no efforts to work for the future that all people is able to use clean electricity energy .

EN

EN

Inquiry Now

Inquiry Now

Tel: +86 15361528965

Tel: +86 15361528965